ABBERMIST LIMITED

Programme Office Specialists

Established 08/11/1985

1969-1973 HMS' Fisgard & Caledonia

ROYAL NAVY

Chief Petty Officer

Marine Engineer Artificer

September 1969 until March 1982

Regards and thanks to Navy Photos, HMS Fisgard and HMS Caledonia contacts for these images.

1981 - 1982 HMS NEPTUNE

In Neptune I worked from a large workshop manufacturing items for submarines, in sheet metal or wood, and carrying out various jobs on board submarines such as electric arc welding, oxy-acetylene welding/burning and general repair work.

1981 HMS BRAZEN

Appointed to this the latest Gas Turbine Frigate being built for the Royal Navy by Yarrows Shipbuilders Ltd. Glasgow, to set up the Engineers Office filing systems, obtain the relevant records and drawings and establish good relations with Yarrows Staff in readiness for the ships own Commissioning Engineers who were to join later on in the ships building programme. This included the attendance of trials, recording of events and the reporting of my observations and suggestions and subsequently filing all data for later use.

My work with Brazen was successfully completed after six months

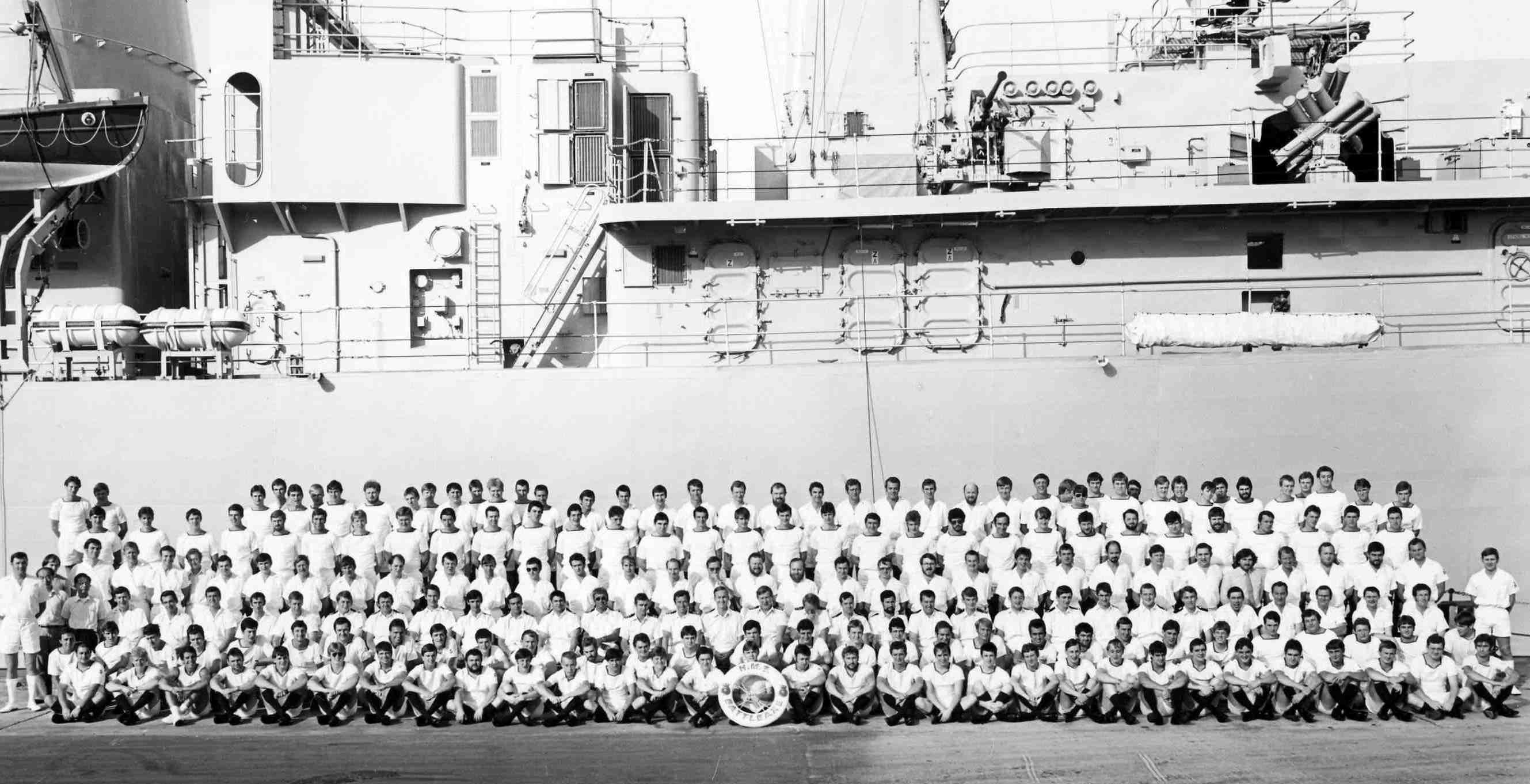

1978-1981 HMS BATTLEAXE

Appointed during the ships construction, to witness and approve the installation, test and trials of machinery.

After the ship commissioned I served on her as a Marine Engineer Artificer 1stClass (Chief Petty Officer) with control of and responsibility for:

The main propulsion plant, which consisted of two Rolls Royce Olympus Gas Generators, developing up to 25000 shaft horse power (ship) (19,2MW) each; two Rolls Royce Tyne Gas Turbines developing 3500 shaft horse power (2.7MW) each; two Browns Gearboxes; Shafts, Controllable Pitch Propellers and associated Hydraulic Systems.

The power generation plant and switchboards, which consisted of four Paxman Ventura 16 cylinder One Megawatt Diesels with Fluidic Control panels. The Generators fed two secondary and one main switchboards, the Main Switchboards being situated in the Ships Control Centre along with all other Main and Auxiliary machinery control and surveillance equipment.

Other main and auxiliary machinery, such as the Electro-Hydraulic Steering System, Desalination Plants, Refrigeration and Air Conditioning Plants, Steam Generators, 120 ton/hr salt water Fire Pumps, Hydraulic Systems, High Pressure and Low Pressure Air Compressors and Systems and Domestic Equipment.

As Shift Charge Engineer, I was responsible to the Marine Engineer Officer/Captain for the correct and safe operation under all power/load conditions, of the Marine Engineering Departments machinery worth over £10 million and for the safety and welfare of all watchkeeping personnel.

Simultaneously I became Plant Maintenance Supervisor for:-

Water Chilling Plants, 4 X 1 million BTU/HR, their associated systems and controls; the chilled water Supply and return system which supplied 19 in number Air Treatment Units for air conditioning and numerous heat exchanges in highly sensitive electronic equipment cabinets.

The Steering Gear system which consisted of two Browns variable delivery hydraulic pumps, two rotary vane actuators, hand pump system, oil cooling system and oil replenishing system.

The General Service Hydraulic system with four MacTaggart Scott rotary hydraulic pumps - output 17.5 gpm at between 145-172 bar - supply various equipments such as capstans, hoists winches and lifts etc.

Refrigeration Plants for food storage Cold and Cool rooms, with two Liqhtfoot compressors, each with their own condensers and cooling systems, a common Liquid receiver and three common evaporators.

The ships stabilisers ‘Browns’, incinerator and garborator units for waste disposal.

1975-1978 HMS AMBUSCADE

Appointed as Marine Engineer Artificer 2nd Class (Petty Officer). After eighteen months gained promotion to Marine Engineer Artificer 1st Class. Main Propulsion Plant and systems controlled whilst on shift were similar to ‘Battleaxe’ above . Plant Maintenance responsibilities were four Paxman 750 KW Diesel Generators; two Weirs Desalination plants; a High Pressure Air system with Compressors, reducers and motors; a Low Pressure Air System with Compressors, reducers and dryers; motor boats with Perkins and Enfield diesel inboard propulsion engines; and forty and twenty horse power outboard motors.

See more at HMS Ambuscade Association Web Site

1973-1975 HMS SCYLLA

Appointed to complete my one year ‘Journeyman's time, during which I gained my Boiler Room Watchkeeping Certificate and was promoted to Marine Engineer Artificer 2nd Class. I had responsibilities for maintenance of two Babcock and Wilcox Superheat Steam Boilers, two AlIens 750 KW Turbo Alternators, and saturated low pressure steam to the domestic heating system.

My Far East Trip with Scylla

U.K., Gibraltar, Simonstown, Mombassa, Bahrain, Kuwait, Bandar Abbass, Singapore, Townsville, Lyttleton, Gisbourne, Sydney, Paulo Tioman, Satahip??, Bankok, Hong Kong, Mahe, Capetown, Gibraltar, U.K.

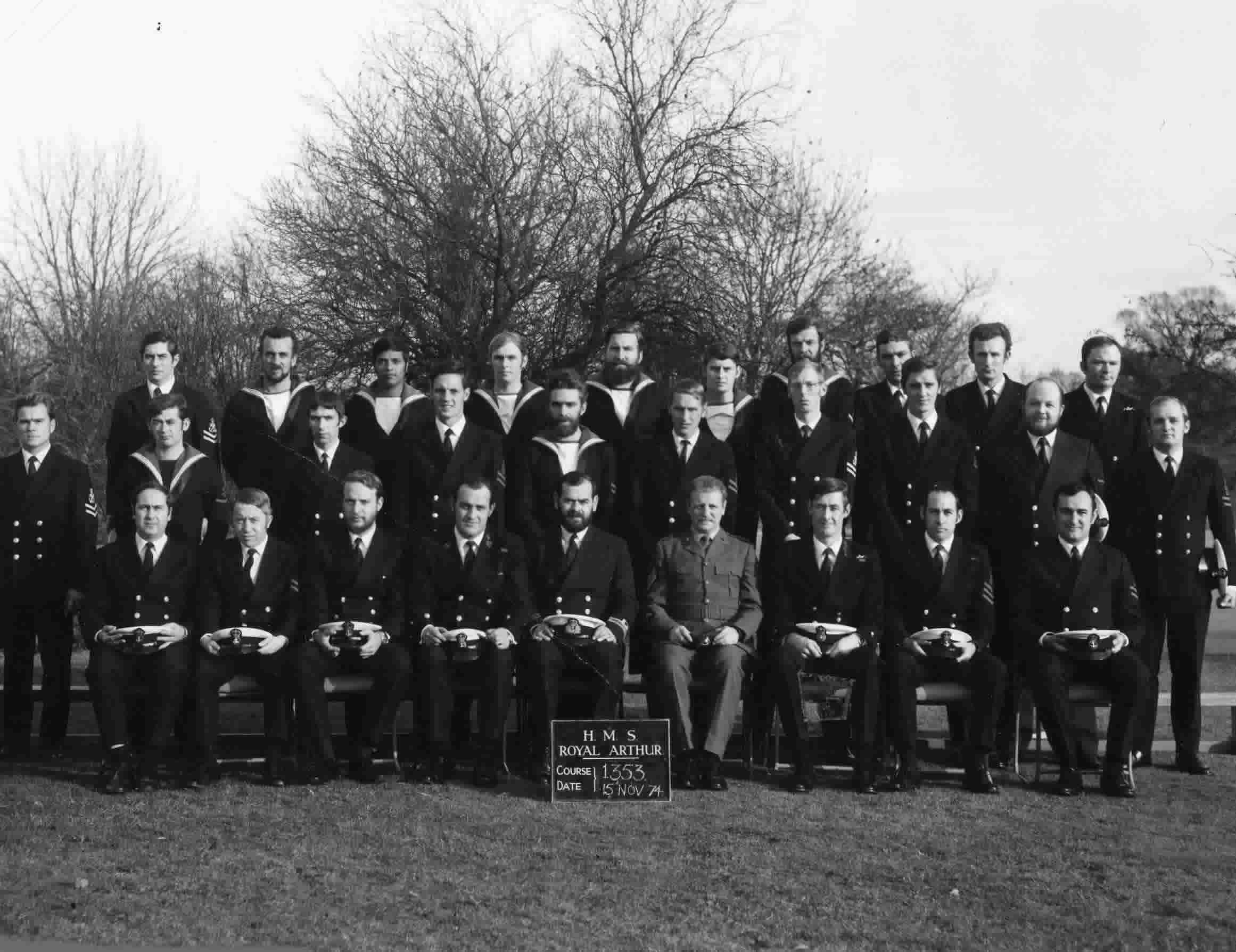

HMS Royal Aurthur

Class 1353 For promotion we had to pass! We did on 15 November 1974

1969-1973 HMS Fisgard and HMS Caledonia

Marine Engineering and Apprentice training Colleges

General

My responsibilities at sea included the control, maintenance and operation of mechanical aspects of the marine propulsion and auxiliary machinery and their associated control systems. I was also responsible for the instruction and supervision of watch-keeping and maintenance personnel and as the Marine Engineering Departments specialist in fault diagnosis and rectification.

During the months between appointments (approx 12 in total), I was part of Fleet Maintenance Groups working from large workshop facilities assisting ships with the heavier maintenance operations and providing specialist knowledge and skills when required.

Throughout my naval career great emphasis was placed on my training in fire prevention, detection and fighting.